5 Processes of Making Injection Molds Techicy

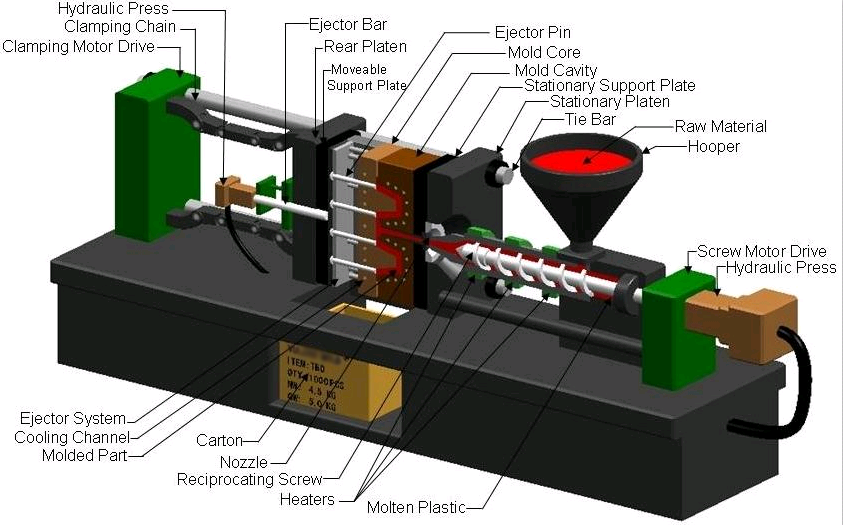

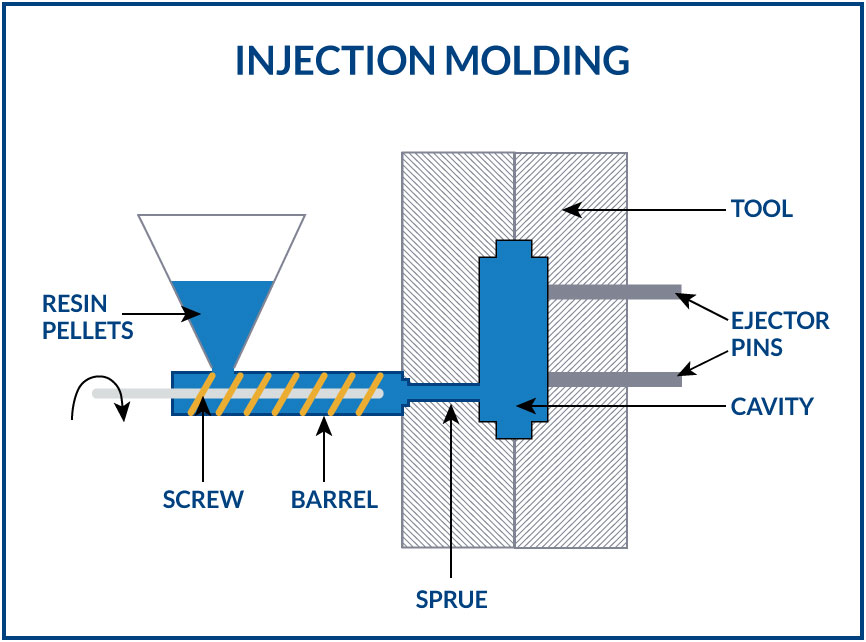

Injection molding is a process in which a thermoplastic polymer is heated above its melting point, resulting in the conversion of the solid polymer to a molten fluid with a reasonably low viscosity. This melt is mechanically forced, i.e., injected, into a mold in the shape of the desired final object.

Schematic drawing of the mold for an injection molding process. The... Download Scientific Diagram

Chem-Trend products improve process efficiency during injection molding. Purging compounds and mold maintenance products to increase quality and productivity.

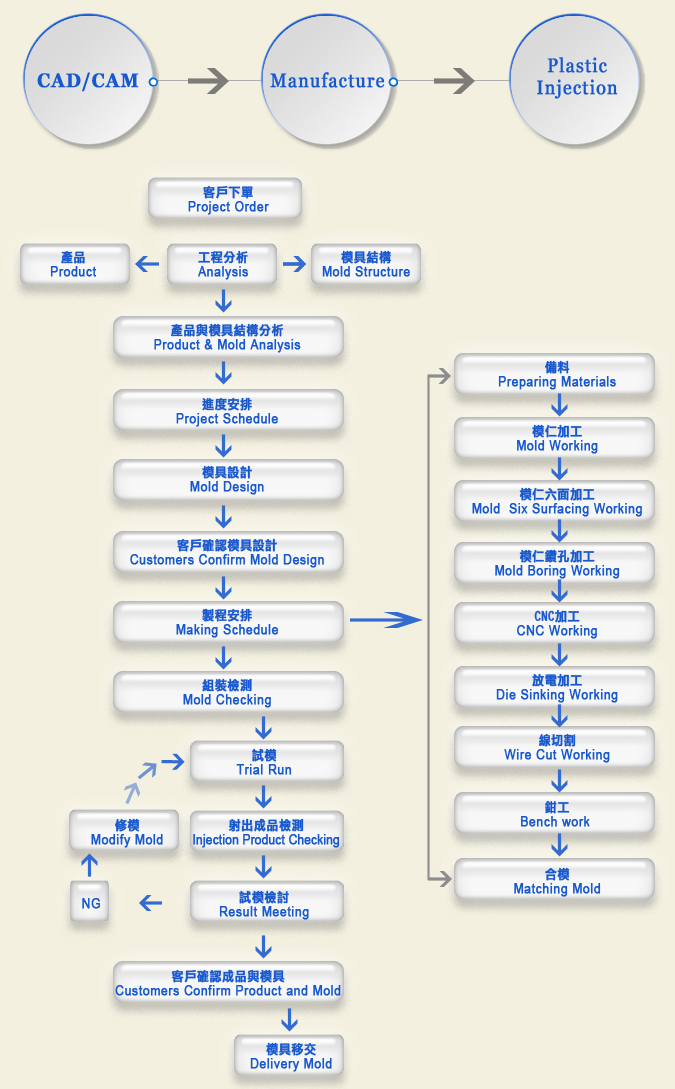

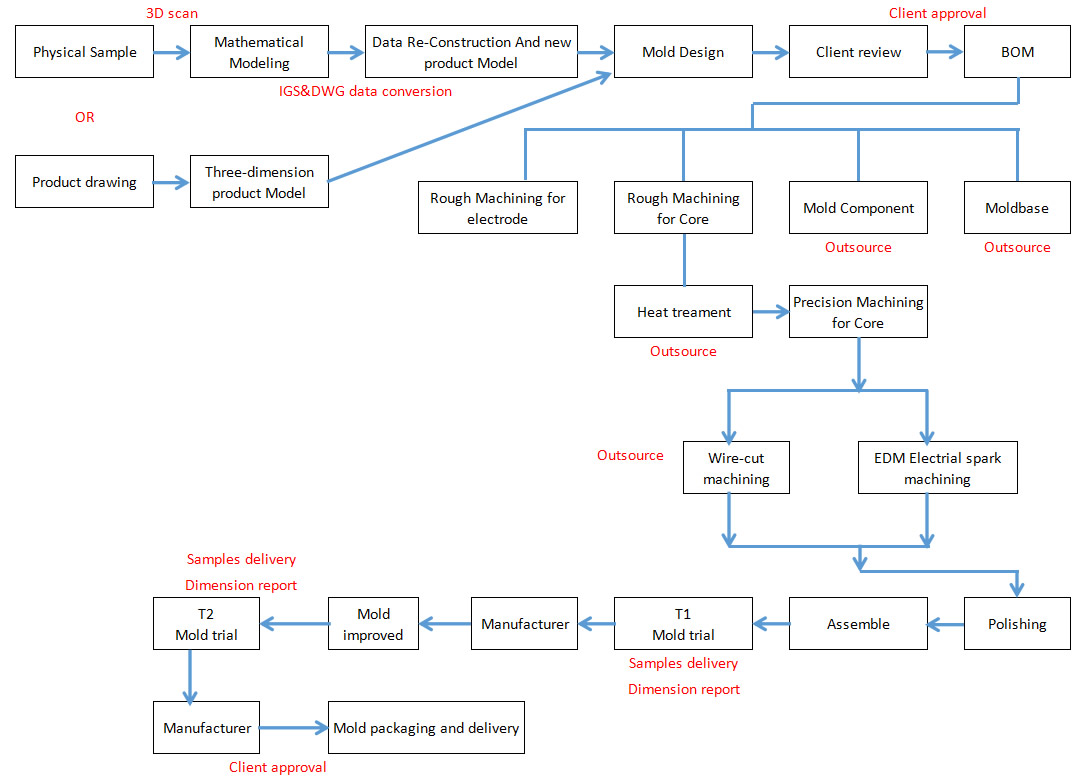

Injection Mold Making Flow Chart KAE LII MACHINE MFG CO LTD

Several studies in the mold industry have been carried out to optimize the mold manufacturing process, it is worth mentioning the study developed by Treno, 2012 [2] on the application of Lean methodologies in the scope of maintenance of a metalworking company producing molds. This study includes an analysis of equipment downtimes and.

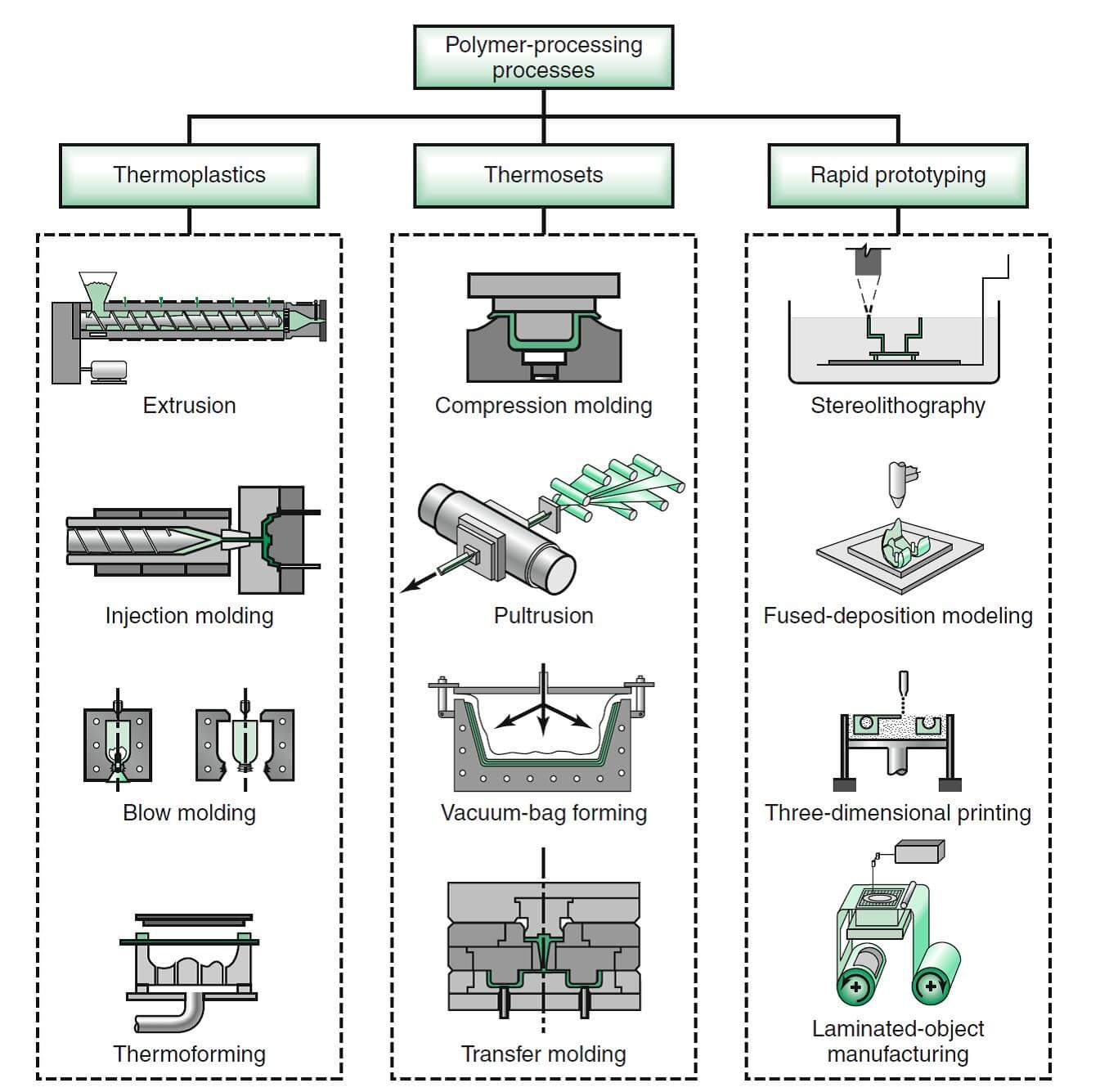

Various Plastic Molding Process

Injection moulding is a manufacturing process that allows for parts to be produced in large volumes. It works by injecting molten materials into a mould (or 'mold' in the United States). It is typically used as a mass production process to manufacture thousands of identical items. Injection moulding materials include metals, glasses.

Plastic Injection Mold maker from China

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold.

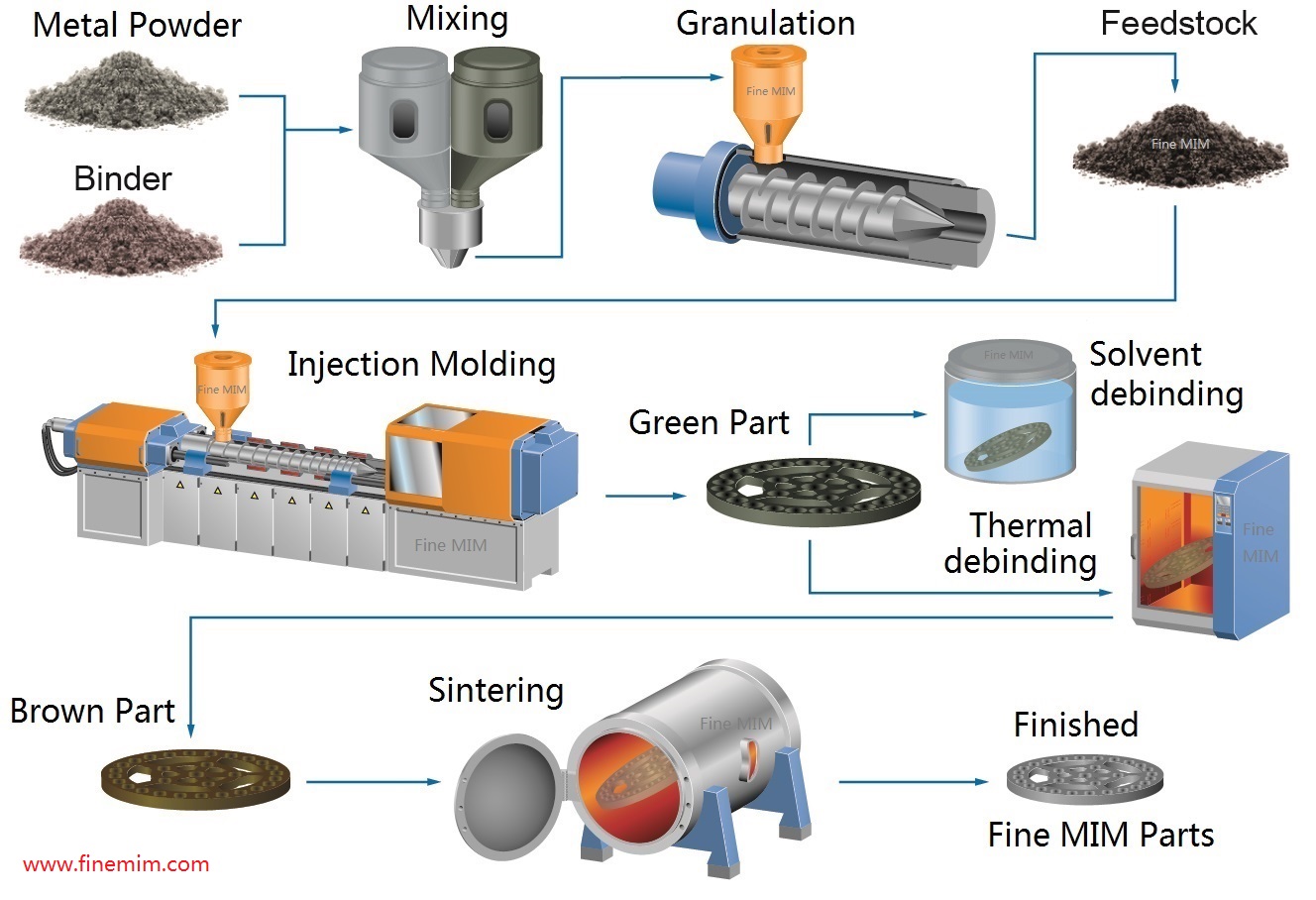

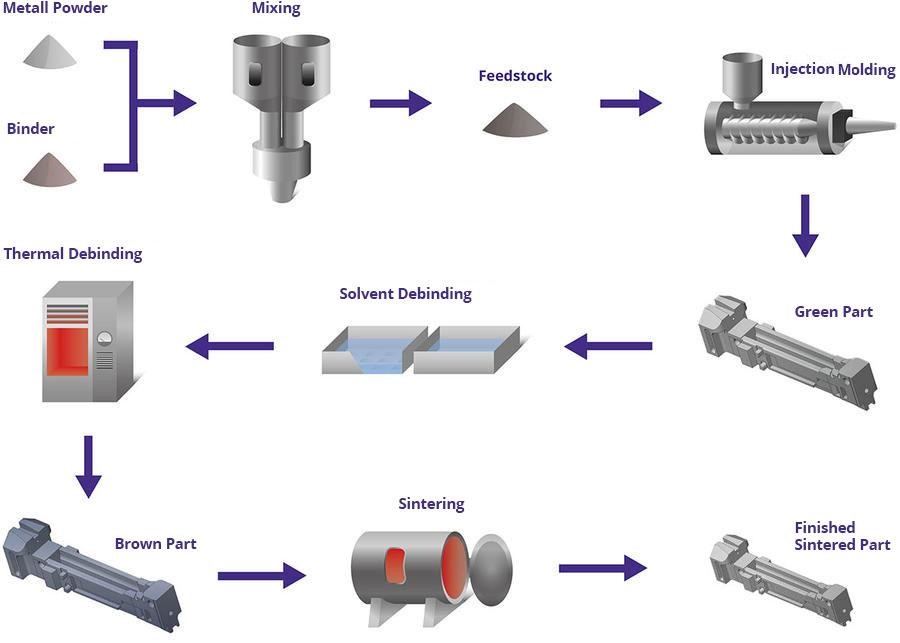

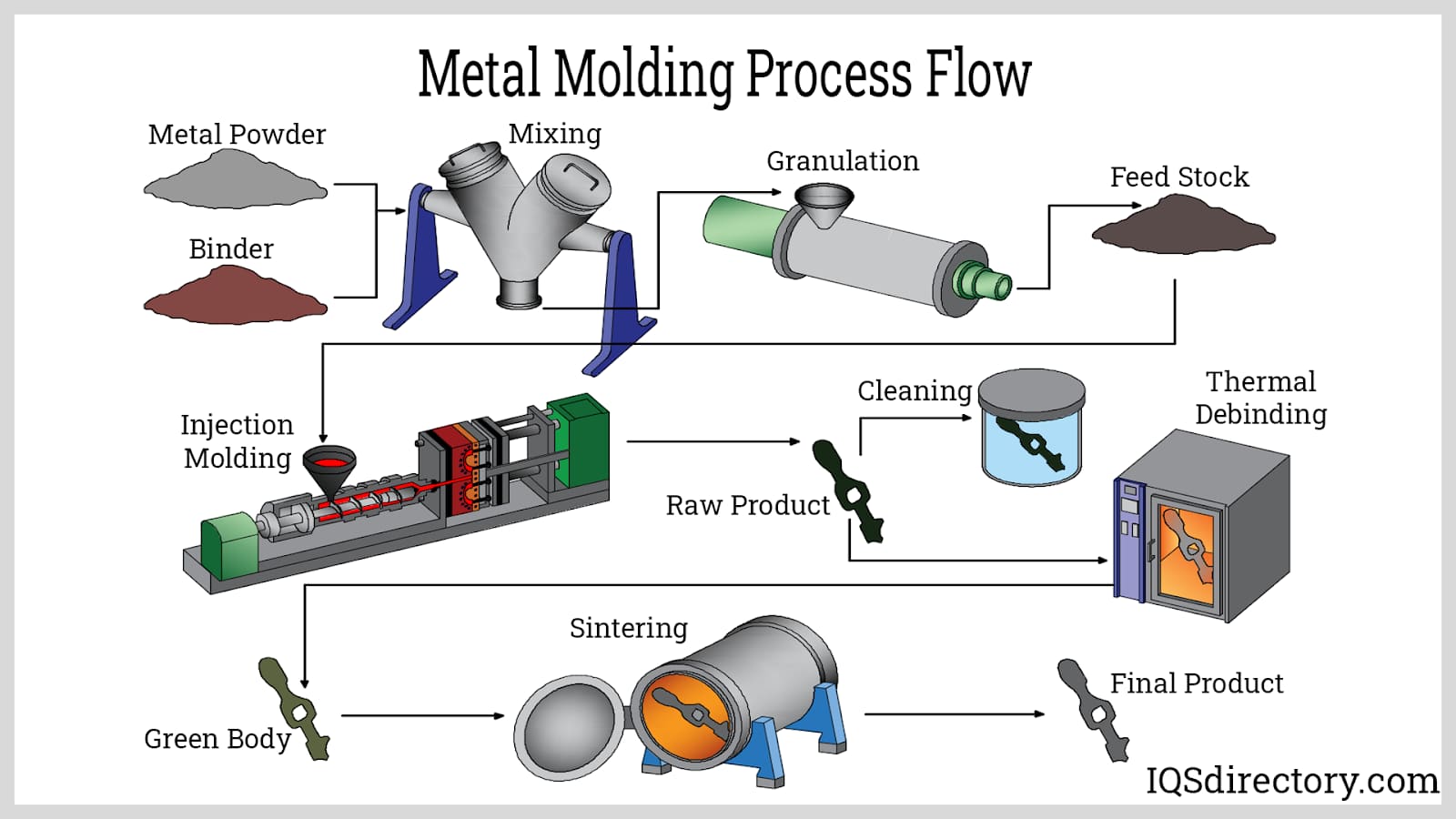

Metal Injection Molding MIM Supplier

Step 1: Mold Design The first step of the process is to finalize your designs for injection molding, which encompasses the part as well as the mold design. Get DFM Feedback Early On to Accelerate the Molding Process

Injection Molding Step by Step How Are Plastic Parts Made?

Molding is the process of shaping a liquid or flexible raw material using a rigid frame called a mold. This process, which is very popular today in many industries, took off at the height of the Second World War when the need for mass-produced products increased.. However, computers have facilitated the entire design and manufacturing.

Hongyan Precision MouldMold Manufacturing

2. The Basics of Injection Molding 2.1 What is Injection Molding? Injection molding is a manufacturing process in which molten plastic material is injected into a mold cavity, where it cools and solidifies to form the desired shape of the final product.

Metal Injection Molding MIM Process FineMIM

A variety of manufacturing processes involve the shaping of malleable raw materials using a designed, fixed tool, structure, or frame-known as the mold. In terms of structure, molds have concave shapes (negative mold) or convex shapes (positive mold) designed according to the final design the manufacturer intends to create.

Metal Injection Molding Advantages, Disadvantages, Process Stages, and Molding Considerations

75 of The Top 100 Retailers Can Be Found on eBay. Find Great Deals from the Top Retailers. eBay Is Here For You with Money Back Guarantee and Easy Return. Get Your Molds Today!

The Mold and Die Manufacturing Process with Machining Center by Liquid Coolant Method. Stock

Molding processes are the major periodic manufacturing operations in the polymer industry. An enormous amount of plastic, rubber, and thermoset parts, ranging from automobile bumpers to personal computers, refrigerator housings to bottles and tires, are produced by molding processes.

One Picture to Understand the Structure of an Injection Mold

The mold manufacturing process for injection molding is referred to as mold tooling. Many molding shops offer mold tooling and design as a service on top of full production injection molding. The majority of these molds are made of steel, but they can also be manufactured from aluminum.

How Mold Manufacturing Works?

In the simplest terms, it's a manufacturing process where molten plastic is injected into a mold, then cooled and ejected as a solid part. But let's break it down a bit more. First, the plastic material, in the form of granules or pellets, is fed into the injection molding machine through a hopper.

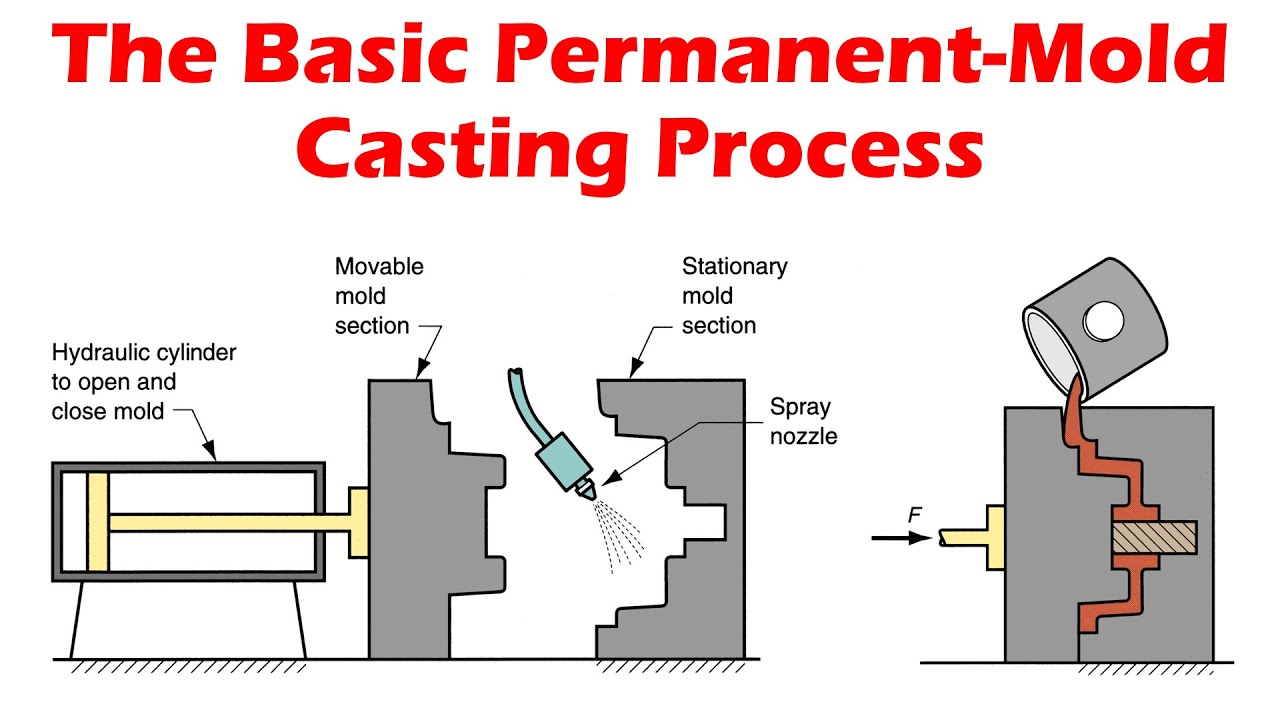

The Basic Permanent Mold Casting Process YouTube

Mold, in manufacturing, a cavity or matrix in which a fluid or plastic substance is shaped into a desired finished product. A molten substance, such as metal, or a plastic substance is poured or forced into a mold and allowed to harden. Molds are made of a wide variety of materials, depending on.

The Beginner’s Guide to Permanent Mold Casting Startup Buzz

Although manufacturing technology has been developing rapidly, injection molding is still widely used for fabricating plastic parts with complex geometries and precise dimensions. Since the occurrence of faults in injection molding is inevitable, process optimization is desirable. Artificial intelligence (AI) methods are being successfully used for optimization in different branches of science.

4 Stages of Injection Molding Process 🥇 Injection Molding Industries

Polymer injection-molding is a standard manufacturing process that is typically characterized by high production volumes [5]. Electricity is required during several steps of this process, from the movements of the machine that allow the closure of the mold, filling the cavity, holding and ejecting